View All Product Categories

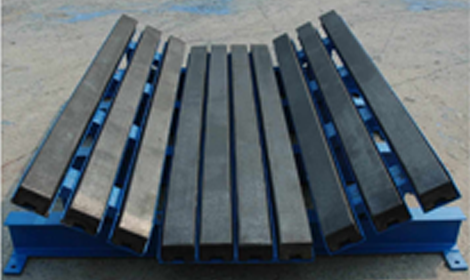

Slag discharge drum

The slag drum is a device used to treat wastewater and solid waste. It is ingeniously designed and can effectively separate solid waste from liquid, thereby achieving the purpose of wastewater treatment and waste cleaning.

Product Specifications

Size: Customized according to customer requirements

Material: High-quality stainless steel

Applicable scenarios: Industrial wastewater treatment, sewage treatment plants, etc.

Product Advantages and Features

Efficient separation: The use of advanced separation technology can efficiently separate solid waste from liquid and improve treatment efficiency.

Durable and reliable: Made of high-quality stainless steel, it is corrosion-resistant, wear-resistant, and can operate stably for a long time.

Environmental protection and energy saving: Advanced technology is used, energy-saving and environmentally friendly, and meets environmental protection requirements.

Product quality inspection

We conduct strict quality inspections on each slag discharge roller to ensure that the product is stable and reliable and meets the customer's use requirements.

Product use

Slag discharge rollers can be widely used in industrial wastewater treatment, sewage treatment plants, urban sewage treatment and other fields. They can effectively separate solid waste from liquid, improve treatment efficiency, and purify the environment.

Product packaging and transportation

We use professional packaging methods to ensure that the product is safe and intact during transportation and reduce transportation risks.

Product precautions

When using the slag discharge roller, please pay attention to safe operation to avoid accidental injuries.

Regularly inspect and maintain the slag discharge roller to ensure the normal operation of the equipment.

If you have any questions or need further consultation, please feel free to contact our customer service staff.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry