View All Product Categories

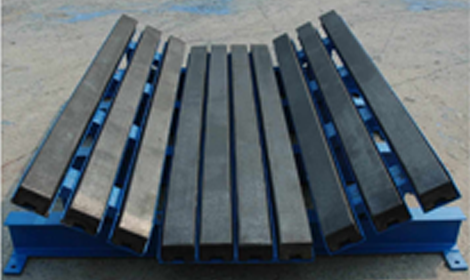

Plough type unloader

The plough unloader is a professional equipment used to unload various materials. Its design is inspired by the plow in agriculture and can efficiently unload materials from containers or vehicles to designated locations.

Product Specifications

Size: According to different models and uses, a variety of sizes and unloading capacity options are available to meet different material unloading needs.

Material: Mainly made of high-quality steel materials, the structure is sturdy and durable, and can withstand high-intensity use.

Power source: The optional power sources include hydraulic systems, electric motors, etc. to meet the needs of different working scenarios.

Others: Some plow-type unloaders are equipped with rotation or tilting functions to increase the flexibility and efficiency of unloading.

Product Advantages and Features

Efficient unloading: The plow type unloader adopts a unique design, which can quickly and smoothly unload materials from the container or vehicle to the designated location, improving work efficiency.

Flexibility: The plow type unloader has good adaptability and can be applied to containers or vehicles of different types and shapes to meet diverse unloading needs.

Easy to operate: The design is simple and the operation is convenient. Operators only need simple training to operate proficiently, which reduces the difficulty of operation and labor costs.

Durable and reliable: Made of high-quality materials and strict processes, the structure is sturdy and durable, and can adapt to various harsh working environments.

Product quality inspection

We conduct strict quality inspection on each batch of impact beds to ensure that the products meet relevant standards and customer requirements. Inspection items include pressure resistance test, wear resistance test, etc.

Product Use

Plough type unloaders are widely used in construction sites, ports, mines and other places to unload various materials such as sand, coal, ore, etc. They are important equipment in the unloading process of modern logistics.

Product Packaging and Transportation

Regularly perform maintenance work on the plow type unloader, including lubrication, cleaning, circuit inspection, etc., to ensure the normal operation of the equipment and extend its service life.

Product Precautions

When operating a plow discharger, ensure that the operator has relevant training and experience and follows safe operating procedures.

During the unloading process, ensure that the work site is safe and orderly, set up obvious safety warning signs to prevent accidents.

Regularly conduct safety inspections on the equipment to promptly identify and deal with potential safety hazards.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry