View All Product Categories

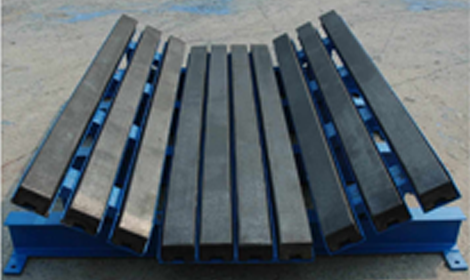

Self-aligning roller

Self-aligning rollers are specially designed rollers for conveyor belt systems. They are designed with a spherical roller structure and can be freely adjusted in angle to solve problems caused by bending or irregular movement in conveyor belt systems.

Product Specifications

Material: usually metal (such as steel, stainless steel)

Diameter: can be customized according to customer needs

Length: can be customized according to customer needs

Spherical roller: contains specially designed spherical rollers with adjustable angles

Product Advantages and Features

Freely adjust the angle: The spherical roller design of the self-aligning roller enables it to freely adjust the angle to adapt to the bending or irregular movement in the conveyor belt system.

Reduce maintenance costs: Effectively reduce wear and friction in the conveyor belt system, reduce maintenance costs and energy consumption.

Improve stability: The self-aligning roller can automatically adjust the angle during the operation of the conveyor belt system, improving the stability and reliability of the system.

Wear and corrosion resistance: Made of high-quality metal, it has good wear resistance and corrosion resistance, and is suitable for conveyor belt systems in harsh environments.

Product Quality Inspection

Each self-aligning roller undergoes strict quality inspection before leaving the factory to ensure that the spherical roller has a stable structure and can adjust the angle flexibly.

Product Use

Self-aligning rollers are suitable for various conveyor belt systems that require angle adjustment, such as curved conveyor belts, irregularly shaped conveyor belts, etc. They are widely used in mining, ports, building materials industry and other fields.

Product packaging and transportation

In order to ensure that the product reaches the customer safely during transportation, the product is properly packaged. Common packaging methods include wooden box packaging or foam plastic packaging.

Product precautions

Please ensure that the roller is aligned with the conveyor belt during installation to avoid friction and unnecessary wear.

Regularly check the use of the trough roller and replace damaged or severely worn parts in time to ensure the normal operation of the conveyor belt system.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry