View All Product Categories

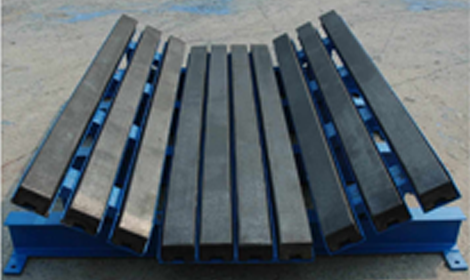

Polymer roller

Polymer roller is a specially designed roller used in conveyor belt systems. The roller body is made of polymer material and has the characteristics of light weight, wear resistance and corrosion resistance.

Product Specifications

Material: polymer material (such as polyethylene, polyurethane, etc.)

Diameter: customizable according to customer needs

Length: customizable according to customer needs

Surface coating: some products may be specially treated to improve wear resistance and corrosion resistance

Product Advantages and Features

Lightweight and high strength: Polymer materials are lightweight and high strength, which can reduce the load on the conveyor belt system and extend the service life of the equipment.

Wear and corrosion resistance: Polymer materials have excellent wear and corrosion resistance, and are suitable for conveyor belt systems in harsh environments, such as humid and corrosive media.

Reduce energy consumption: The polymer roller has a smooth surface and a low friction coefficient, which reduces friction with the conveyor belt and reduces energy consumption.

Low maintenance cost: Polymer rollers have a long service life and stable performance, reducing maintenance and replacement costs.

Product Quality Inspection

Each polymer roller undergoes strict quality inspection before leaving the factory to ensure that the material quality, dimensional accuracy, surface finish, etc. meet the standard requirements.

Product Use

Polymer rollers are suitable for various conveyor belt systems and are widely used in mines, ports, logistics warehousing and other fields to support and guide conveyor belts and improve conveying efficiency.

Product packaging and transportation

In order to ensure that the product reaches the customer safely during transportation, the product is properly packaged. Common packaging methods include wooden box packaging or foam plastic packaging.

Product precautions

Please ensure that the roller is aligned with the conveyor belt during installation to avoid friction and unnecessary wear.

Regularly check the use of the trough roller and replace damaged or severely worn parts in time to ensure the normal operation of the conveyor belt system.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry