View All Product Categories

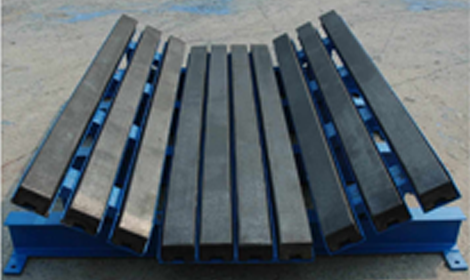

Friction roller

The friction roller is a key component used in conveying systems. It transmits power through friction to ensure smooth transportation of materials. It is made of highly wear-resistant materials and has good durability and stability.

Product Specifications

Material: polyurethane/metal

Diameter: customized according to needs

Length: customized according to needs

Surface treatment: chrome plating/spraying, etc.

Product Advantages and Features

High wear resistance: Made of high-quality materials, it has excellent wear resistance and can operate stably for a long time.

Excellent transmission effect: Power is transmitted through friction, making the conveying system run more smoothly and efficiently.

Anti-slip design: The surface texture design effectively prevents materials from sliding and improves transportation efficiency.

Low noise: Careful design and the selection of high-quality materials make the product run with low noise and improve the comfort of the working environment.

Product Quality Inspection

We strictly follow international standards for production and testing to ensure that the quality of each product meets the requirements and expectations of customers. From raw material procurement to production and manufacturing, to final product inspection, we ensure that every link is strictly monitored to ensure stable and reliable product quality and performance.

Product Use

Friction rollers are widely used in various conveying systems, such as logistics transportation, industrial production lines, etc. Whether in the field of warehousing and logistics or in the manufacturing process, our products can provide you with reliable conveying solutions.

Product packaging and transportation

In order to ensure that the product reaches the customer safely during transportation, the product is properly packaged. Common packaging methods include wooden box packaging or foam plastic packaging.

Product precautions

Please ensure that the roller is aligned with the conveyor belt during installation to avoid friction and unnecessary wear.

Regularly check the use of the trough roller and replace damaged or severely worn parts in time to ensure the normal operation of the conveyor belt system.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry