View All Product Categories

Iron remover

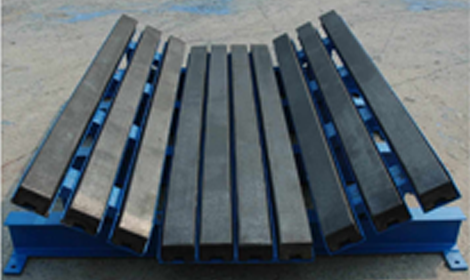

Conveyor iron remover is a kind of equipment specially used to remove iron impurities in conveyor material flow. It is usually used in various material conveying systems, such as ore, coal, cement and other industries, to ensure the quality of material flow and the normal operation of equipment.

Product Specifications

Size: A variety of sizes and models are available to suit conveyors of different sizes and types.

Material: Made of high-quality stainless steel and special magnetic materials, it has good corrosion resistance and durability.

Color: Usually metallic or gray, with a simple and elegant appearance.

Others: Conveyor iron removers of specific sizes and functions can be customized according to customer needs.

Product Advantages and Features

Efficient iron removal: The conveyor iron remover uses a strong magnet system, which can quickly and effectively adsorb and remove iron impurities in the conveyor material flow.

Customized design: Customized design is provided according to different conveyor models and material characteristics to ensure high-quality iron removal effects.

Stable and reliable: The iron remover has a sturdy structure, stable and reliable operation, and is suitable for various harsh working environments.

Easy to operate: Simple design, easy operation, convenient maintenance, reducing maintenance costs and downtime.

Product quality inspection

We strictly follow the quality management system to control product quality to ensure that the quality of each conveyor iron remover meets the standard requirements and is stable and reliable.

Product Use

Conveyor iron removers are widely used in various material conveying systems, such as belt conveyors, bucket elevators, etc., to remove iron impurities in the material flow and ensure the normal operation of the conveying system and product quality.

Product Packaging and Transportation

We use professional packaging materials and methods to ensure that the products reach customers safely during transportation. Each product is carefully packaged to prevent damage and deformation.

Product Precautions

Before installing and using the conveyor iron remover, please read the product manual carefully and install and use it correctly according to the operating requirements.

When cleaning and maintaining the iron remover, be sure to turn off the power and take necessary safety measures to prevent accidents.

If you encounter any faults or problems during use, please contact our after-sales service team in time for processing.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry