View All Product Categories

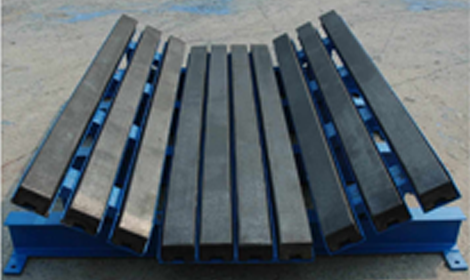

Cleaner

The conveyor cleaner is a tool specially designed for cleaning and maintaining transport machinery and equipment. It can effectively remove dust, debris and sundries from the surface of the conveyor and surrounding areas to keep the equipment in good operating condition.

Product Specifications

Size: Adapt to different types of conveyors to ensure a perfect match.

Material: Made of durable metal and engineering plastic, it has excellent wear resistance and durability.

Color: Usually bright colors, easy to identify and clean.

Others: Equipped with brushes of special shapes and lengths to meet the cleaning needs of various parts of the conveyor.

Product Advantages and Features

Customized design: Customized designs are available for different types and sizes of conveyors to ensure high-quality cleaning results.

Efficient cleaning: Equipped with powerful brushes and dust suction devices, it can quickly and thoroughly remove dirt from the surface of the conveyor and surrounding areas.

Durable and reliable: Made of high-quality materials, the structure is sturdy, durable and reliable, and can adapt to harsh working environments.

Convenient operation: The design is simple and easy to use, and the operation is convenient, even in a small space.

Product quality inspection

We conduct product testing in strict accordance with quality standards to ensure that each conveyor cleaner meets high quality requirements and can operate stably and reliably.

Product Use

Conveyor cleaners are suitable for various types of conveyor equipment, including conveyor belts, belt conveyors, bucket elevators, etc. It can be used to clean the surface of equipment, remove deposits, and prevent dirt accumulation, thereby extending the service life of the equipment and improving work efficiency.

Product Packaging and Transportation

We use professional packaging methods to ensure that the conveyor sweeper is safe and intact during transportation. Each product is strictly packaged to prevent damage or collision during transportation.

Product Precautions

When operating a plow discharger, ensure that the operator has relevant training and experience and follows safe operating procedures.

During the unloading process, ensure that the work site is safe and orderly, set up obvious safety warning signs to prevent accidents.

Regularly conduct safety inspections on the equipment to promptly identify and deal with potential safety hazards.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry