View All Product Categories

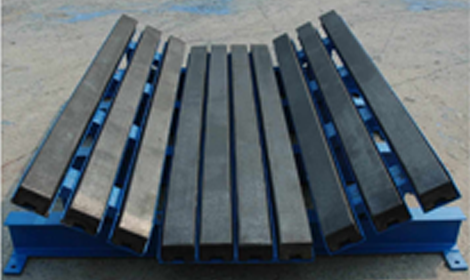

High angle conveyor belt

The high-angle conveyor belt is a kind of conveying equipment specially designed for conveying materials in a vertical or nearly vertical direction. It has a special angle design, which can effectively increase the height and angle of material conveying, and is suitable for material conveying needs in mines, construction, ports and other places.

Product Specifications

Size/Dimensions: Various width and length options are available to meet the needs of different places.

Angle Range: Different angle ranges can be designed according to the specific needs of customers, usually up to 90 degrees or more.

Material: Mainly composed of rubber, steel and fabric, ensuring the strength and durability of the product.

Color: Usually black or other colors to meet the needs of different environments.

Product Advantages and Features

Advantage 1: Efficient transportation, able to achieve rapid conversion from horizontal to vertical, and improve the height and angle of material transportation.

Advantage 2: Space saving, compared with traditional horizontal transportation methods, high-angle conveyor belts can save a lot of space and costs.

Advantage 3: Wide range of applications, can transport various types of materials, such as coal, ore, grain, etc.

More advantages: Wear resistance, long service life, easy installation, etc.

Product Quality Inspection

We conduct strict quality control on each batch of high-angle conveyor belts to ensure that the products meet relevant standards and specifications. We conduct multiple quality tests, including strength tests, wear resistance tests, etc. to ensure the performance and reliability of the products.

Product Use

Large-angle conveyor belts are suitable for material conveying needs in various industries, such as mines, construction, ports, etc. It can be used for horizontal, inclined or vertical conveying to ensure stable material conveying.

Product Packaging and Transportation

We use professional packaging materials and methods to ensure that the products reach customers safely during transportation. Each product is carefully packaged to prevent damage and deformation.

Product Precautions

Please choose the appropriate specifications and inclination range according to actual needs.

During use, please avoid damage to the surface of the conveyor belt by sharp objects.

If there are any quality problems or difficulties in use, please contact our customer service team in time for processing.

Production Process

After-sales Service

Fields

01

Metallurgical Industry

02

Coal Industry

03

Hydropower Industry

04

Building Materials Industry

05

Chemical Industry

06

Grain Depot Industry